If your business generates a significant amount of waste, a commercial trash compactor can be a game-changer - cutting down on hauling costs, improving site cleanliness, and streamlining waste management. With several types of compactors on the market, choosing the right system starts with understanding how each one works and where it fits best.

This guide breaks down the core types of commercial trash compactors, their key features, common use cases, and what to consider before buying - giving you the insight you need to make an informed decision for your facility.

What is a Commercial Trash Compactor?

We’ll start with the basics—what exactly is a commercial trash compactor, and what is its function?

A commercial trash compactor is a specialized waste management system designed to compress large volumes of waste into smaller, more manageable loads. By reducing the size and frequency of waste pickups, compactors help businesses save on hauling costs, maintain cleaner facilities, and improve operational efficiency.

Commercial trash compactors are essential equipment in industries like manufacturing, food service, healthcare, and retail, where efficient waste management is critical. From cardboard and packaging to general refuse, compactors are a practical solution for businesses looking to streamline their waste handling process.

Commercial compactors can be broadly categorized based on how they function into auger and hydraulic compactors.

What is an Auger Compactor?

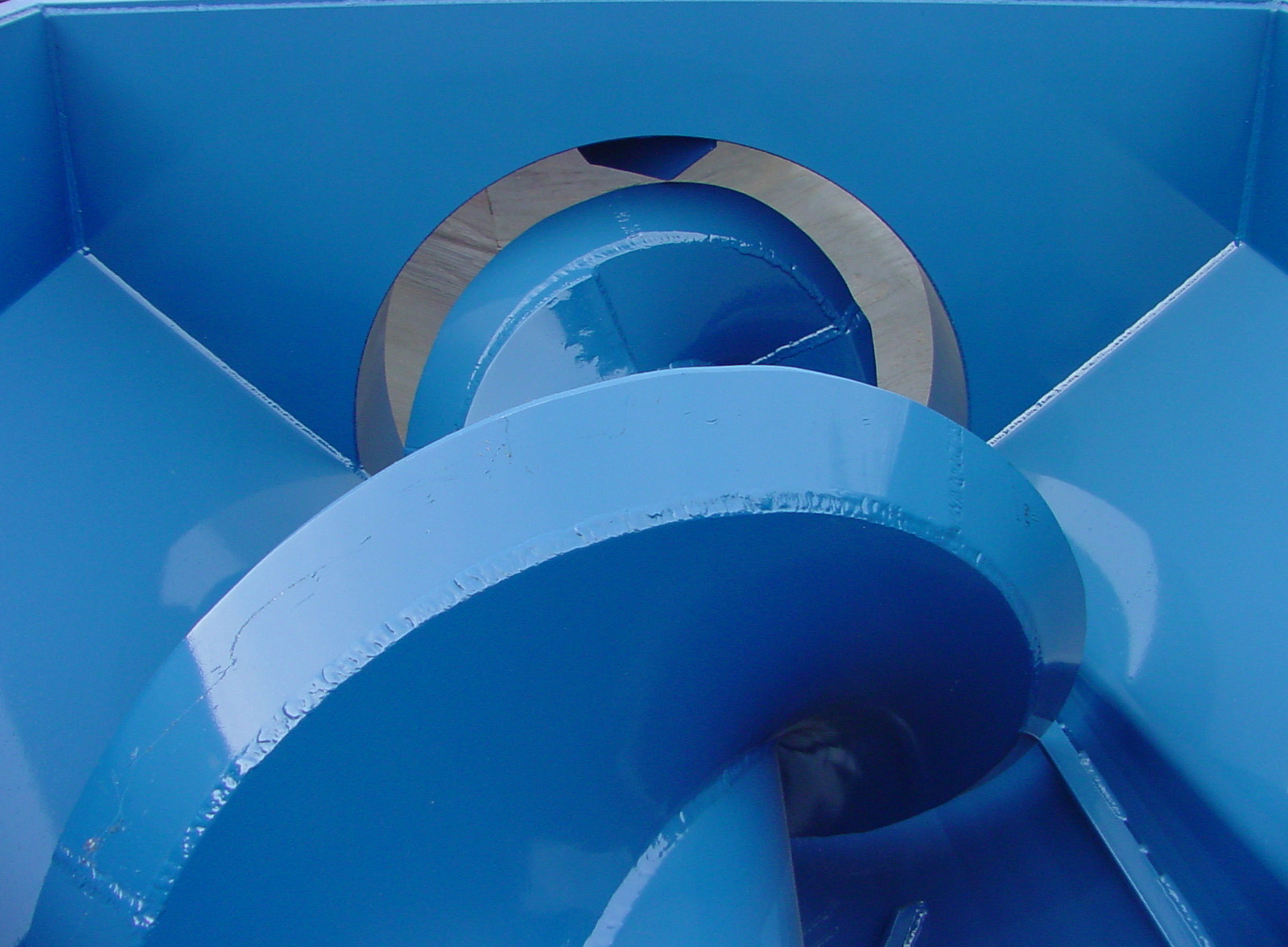

An auger is a tool designed to drill or bore into materials, typically featuring a helical screw blade.  In a compactor, this same principle is applied to manage waste. The auger compactor uses a continuously rotating auger bit to break down and compact waste as it’s fed into the machine. Unlike traditional hydraulic systems that operate in a start-stop motion, auger compactors provide constant forward motion, allowing for faster processing and more efficient compaction.

In a compactor, this same principle is applied to manage waste. The auger compactor uses a continuously rotating auger bit to break down and compact waste as it’s fed into the machine. Unlike traditional hydraulic systems that operate in a start-stop motion, auger compactors provide constant forward motion, allowing for faster processing and more efficient compaction.

This continuous operation offers several advantages:

- Faster processing speeds, which is ideal for high-volume waste

- Uninterrupted waste feeding, reducing bottlenecks and keeps operations moving

- Fewer jams as the auger naturally grinds through most materials

- Low maintenance due to their simple design. Sanitech Auger Compactors are equipped with an automatic lubrication system and the only maintenance needed is the periodic filling of this grease reservoir that lubricates the auger bearings.

Because of these benefits, auger compactors are often used anywhere waste needs to be processed quickly with minimal downtime.

What is a Hydraulic Compactor?

A hydraulic compactor uses hydraulic pressure—created by fluid-driven pumps—to power a ram that compresses waste material. Once waste is loaded into the compaction chamber, the hydraulic system pushes it forward in a back-and-forth motion, compressing the material and transferring it to a container for hauling.

Hydraulic compactors have been an industry standard for decades. However, their design comes with limitations. The stop-start cycle of the hydraulic ram can slow down processing, especially in high-volume operations. This motion also increases the chance of material jams, which often require manual intervention to clear. In some cases, operators may need to enter the chamber, posing serious safety risks and potential downtime.

Learn more about the differences between hydraulic and auger compactors.

Choosing a Commercial Trash Compactor

The first step is deciding between a hydraulic or auger compactor. Which is better for your facility? Both serve the same core purpose, but how they operate—and the impact they have on your workflow—is vastly different.

The stop-and-start motion of hydraulic compactors can slow processing, increase downtime, and require more frequent maintenance. For businesses that can’t afford bottlenecks or safety risks, this creates real operational challenges.

More and more facilities are switching to auger compactors. Their continuous operation, low maintenance design, and high-throughput performance make them an ideal choice for businesses that need speed, reliability, and cost control.

If you're looking for the most efficient long-term solution, an auger compactor will outperform a hydraulic model in nearly every key category. View a full breakdown of available auger models and features.

Benefits of Using a Commercial Auger Compactor

Investing in a commercial trash compactor - more specifically, an auger compactor - brings many benefits that can improve business operations.

Cost-Savings

Commercial trash compactors are an investment, but one that results in significant long-term savings. Faster and more efficient waste compression reduces the frequency of waste pickups, lowering disposal costs and minimizing labor expenses related to handling waste.

Site Cleanliness

Auger compactors are continuously working to break down waste, which results in less build-up and overflow. This is particularly significant for hospitals or business in food service - like bakeries or restaurants. Minimizing odors and keeping waste at bay helps to create a cleaner, more sanitary environment that is welcoming to customers or patients. Since auger compactors don't use hydraulics, there is also no risk of leaks.

Durable & Reliable

Constructed with high-quality, industrial-grade materials, commercial trash compactors are designed to withstand high demands and daily use. Whether it’s dealing with cardboard, packaging, or wet waste, compactors are built to endure wear and tear, ensuring long-term performance and minimizing the need for costly repairs or replacements.

Environmentally Sustainable

High compaction ratios reduce the volume of waste per haul, resulting in fewer pickups. This directly translates to lower fuel consumption and fewer trips made by waste management trucks. As a result, businesses can significantly reduce their carbon footprint and contribute to fewer CO2 emissions.

What are the Different Types of Auger Compactors?

Auger compactors are available in several different variations. Each is designed for different facility layouts and waste types.

Here’s a closer look at the main types of compactors and where each one fits best.

Ideal for dry waste like cardboard, packaging, and general refuse. These systems stay fixed in place while waste is compacted into a separate roll-off container.

Stationary compactors work well for:

-

Food Service & Hospitality: Bakeries, restaurants, hotels, and cinemas

-

Industrial & Manufacturing: Factories, distribution centers, and logistics hubs

-

Retail & Commercial: Shopping centers, grocery stores, and office parks

-

Institutions: Schools, hospitals, apartment complexes, and government buildings

Designed for wet waste or messy materials. The compactor and container are built as a single sealed unit to prevent leaks and odors.

Self-Contained Compactors work well for:

-

Food Service & Hospitality: Bakeries, restaurants, hotels, and cinemas

-

Healthcare & Institutions: Hospitals, nursing homes, and correctional facilities

-

Grocery & Food Processing: Supermarkets and food manufacturing facilities

Helpful Add-ons & Specialized Equipment:

-

Cart Dumpers – Great for facilities where staff routinely handle heavy loads of waste. Cart dumpers automate the lifting and loading process to improve safety and efficiency.

-

Cane Dumpers – Another type of cart dumper, these are used when an elevated dump height is needed.

-

Bottle Busters - Specialized compactors designed to break down glass bottles and containers, reducing the volume of waste and making recycling more efficient.

What Should I Consider Before Buying?

Not every business has the same waste management needs. Here are some important factors to consider before purchasing a commercial trash compactor:

1. Type of Business

As outlined in the section above, the type of business you run determines which compactor is best. While both stationary and self-contained compactors work well for industries like retail, food, residential and commercial buildings, schools, and prisons, stationary compactors are better suited for manufacturing companies and distribution facilities.

2. Type of Waste

Is your waste mostly dry (cardboard, packaging, pallets), or are you dealing with wet or organic materials (food waste, liquids)?

Similarly, you should consider add-ons depending on the waste your business produces.

- Liquid Drain System: This optional add-on by Sanitech Auger Compactors ensures that liquids are drained out of the compactor and receiver bin before hauling. Removing liquids will reduce the risk of liquid spillage during bin separation and reduce the weight of the compacted material.

- Bottle Busters: Designed to crush glass bottles and containers, reducing waste volume and improving recycling efficiency. This add-on is particularly useful for businesses in the food and beverage industry or those that process high volumes of glass waste.

3. Volume of Waste

The amount of waste your business generates plays a crucial role in determining the right compactor. High-volume operations—such as large-scale manufacturing plants, distribution centers, or food processing facilities—benefit from heavy-duty compactors that can handle continuous use without frequent emptying. Auger compactors, known for their fast, high-throughput performance, are ideal in these cases.

On the other hand, smaller businesses or those with lower waste output may prefer compactors with smaller capacities, which are more cost-effective and space-efficient.

4. Space and Footprint

Auger compactors are smaller than hydraulic compactors, but it's still important to consider your space before buying. At Sanitech, we create custom auger compactors to fit your specific layout needs. View our customizable features.

5. Material Handling and Hauler Compatibility

An often overlooked—but critical—part of your compactor setup is how waste is moved from the point of generation to the compactor, and then to the hauler. Proper handling and compatibility ensure safe, efficient, and uninterrupted waste flow.

-

Chutes and Hoods: Ideal for multi-level buildings or facilities with restricted access points, chutes and hoods allow waste to be deposited safely and cleanly into the compactor from upper floors or enclosed spaces. They help streamline disposal and improve site cleanliness.

-

Bins and Tow Carts: For larger facilities or operations with multiple waste collection points, bins and tow carts make it easy to transport material to the compactor. They reduce manual handling, improve efficiency, and help keep workflows organized—especially when integrated with automated feeding systems like cart dumpers.

Commercial Trash Compactors: A Better Way to Handle Waste

Choosing the right commercial trash compactor can make a significant impact on your facility’s efficiency, cleanliness, and long-term operational costs. Whether you’re managing dry waste in a manufacturing plant or food waste in a restaurant, understanding the core types of compactors—and how they perform—is key Learn about commercial trash compactors, including types, features, use cases, and key buying factors. Streamline waste management with a commercial auger compactor.to making an informed decision.

While hydraulic systems have long been the standard, auger compactors offer a modern, more efficient solution for businesses that demand reliability, speed, and lower maintenance. With multiple configurations and customization options available, auger compactors can meet the needs of a wide range of industries and facility layouts.

Streamline Your Waste Management with Sanitech Auger Compactors

Sanitech auger compactors are designed to handle high volumes, reduce hauling costs, and keep your operation running smoothly—with less downtime and fewer maintenance concerns.

Let Sanitech design the right compactor for your business. Contact us today to get started!